ExaPlex is a startup based in Reno, Nevada, USA. We are developing an innovative rod and connector construction toy along with original educational materials that support learning across all STEAM (Science, Technology, Engineering, Art, Mathematics) topics.

We are working to make ExaPlex accessible to everyone worldwide, inspiring people of all ages and backgrounds to build, explore, and learn.

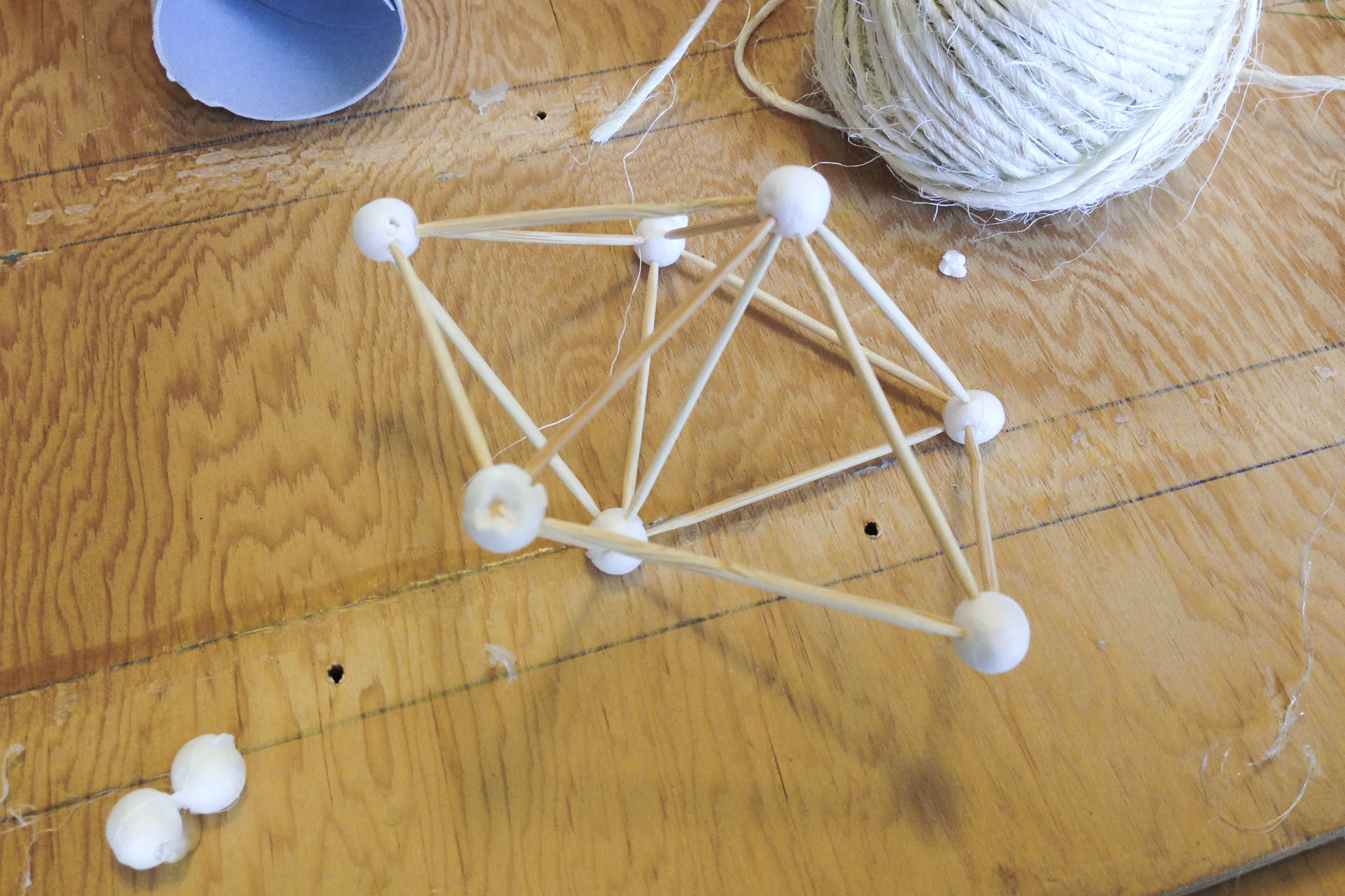

Our patent-pending design features make building more tactile and fun, while also being cheaper and easier to manufacture than other construction toys.

Our supporting materials center around hands-on building and play, connecting physical exploration with abstract academic concepts across the arts and sciences, and practical applications in the real world.

How was ExaPlex invented?

ExaPlex was invented by Max Bielenberg, a designer and engineer living in Nevada, USA. The spark of inspiration came during the Covid lockdown of 2020, when like many parents Max was looking for creative ways to engage with his two children at home.

While crafting with toothpicks and small polystyrene balls he noticed that building large models was difficult and required both more accuracy to avoid unwanted tolerance build-up and flexibility to allow for repositioning and tweaking during larger builds — seemingly conflicting requirements.

Drawing on his background in design engineering and material science, and inspired by the accessible designs of Arvind Gupta (Toys from Trash) Max developed designs for a construction system that could support building large, complex models and be simple enough to make easily and affordably.

Max recalls three pivotal moments in the development process:

I have experience designing plastic parts so the idea of using flexible plastic hinges for the connectors came quite quickly, but the first 3D printed prototypes were actually amazingly good. Building that first model was really fun — fast and satisfying with a very nice result. I realized there was something in this.

After iterating the design and material choice and building more models, he showed the design to some of his friends:

I showed it to one of my smartest friends. He took a look and said 'Better than Lego.' I thought that was a useful first impression.

After filing a provisional patent, Max wanted to test the idea with a wider audience outside of friends and family. He arranged to set up a demonstration table at a local café, where passersby of all ages could try building with the prototype parts.

A lady really got in to it and said 'If I had this at school, I'd be good at math.' That comment made me see the educational opportunity and inspired me to work to scale up the idea and make it available to everyone.

This feedback crystallized the vision for ExaPlex not just as a fun construction toy, but as a tool that supports learning and understanding of geometry and space, and STEAM concepts through hands-on play and exploration.

What next for ExaPlex?

ExaPlex is currently in active development, and we're seeking strategic partners to help us realize our vision of scaling worldwide. If you're interested in collaborating with us, please get in touch.

Our current development focuses on three main areas:

Connector Durability

Improving the strength and longevity of connectors through design and toolpath optimization, and materials research.

Learning Resources

Expanding our library of Shapes, Challenge Cards and materials for educators and parents to support hands-on learning.

Maker Community

Establishing up a distributed network of makers who can 3D print ExaPlex for builders and learners in their communities.

In addition, we're exploring injection molding and other manufacturing methods to scale production while maintaining affordability and quality.